As the summer months approach and the air getting warmer and dryer it is safe to say the risk of dust explosions will increase. Given the dire consequence this is always something to bear in mind when thinking about safety in your workplace.

Although they are considered rare, the consequences are incredibly devasting as outlined in these events below

Tilbury Port on 3 July was described as “like a bomb going off” with flames 75m (246ft) high.

A metal dust explosion in 2014 caused a blast that tore through a plant in eastern China, killing 75 people.

And 14 people died in an explosion at a sugar refinery, caused by exploding sugar dust, in the US state of Georgia.

(Tilbury Port Grain store blast caused by ‘dust explosion’ – BBC News)

In order to understand how to prevent such events its important to understand the conditions which create them

What Causes Dust to Explode?

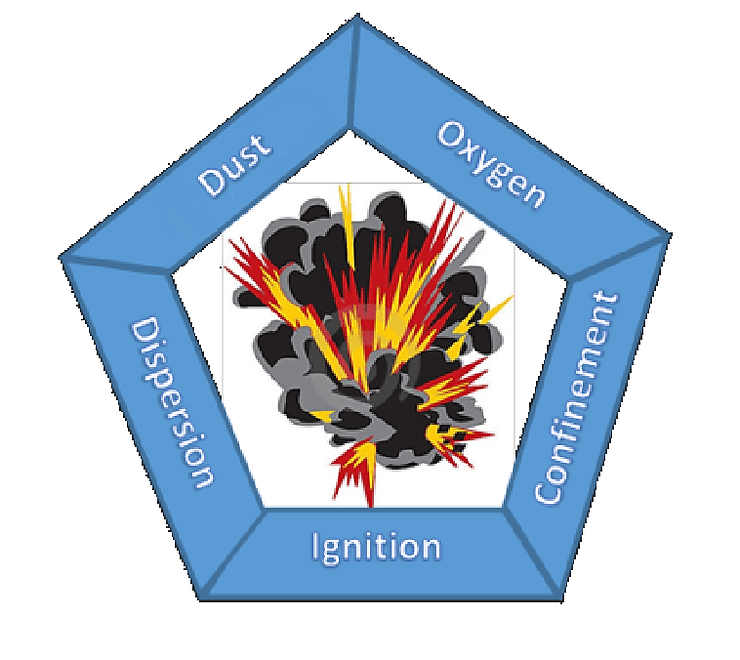

For a dust explosion to occur, five key elements need to be in place, including:

- Combustible dust

- Air/oxygen

- Ignition source

- Confined space

- Dispersion – air movement.

It’s important to note that even without the confinement of the dust particles, an explosion can still occur if the other four elements are present simultaneously.

How to prevent a Dust explosion

In the UK, there are regulations that cover the identification, evaluation, prevention, and/or mitigation of dust explosion risks. Risk assessment is the first step, and areas to consider include the dust’s ability to explode, the likelihood of a dust explosion happening, and who would be at risk in the event of an explosion.

Control measures typically focus on the conditions inside the dust handling system, including controlling the formation of a dust cloud, preventing the creation of an explosive atmosphere, ensuring potential sources of ignition are kept away from the dust, and monitoring and controlling plant performance.

At LEV Extraction Services, we specialize in the design and development of industrial ventilation systems, working with businesses to identify the risk of dust explosions and putting in place the necessary systems and processes to manage them.

Our team provides advice and guidance on ensuring the extraction system catches all the dust, checking the filter’s design, controlling the ventilation system’s location and siting, and maintaining and cleaning out dust deposits to prevent potentially dangerous dust clouds.