TESTING | SERVICING | SPARES AND REPAIRS

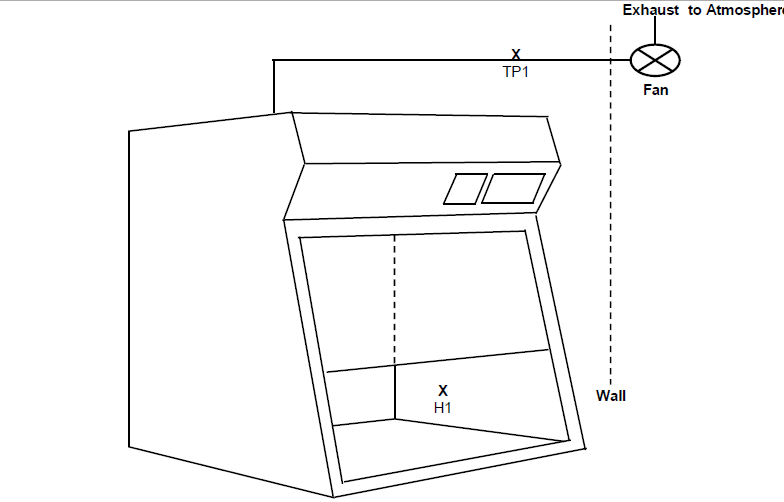

We provide COSHH compliant LEV testing on all LEV extraction systems at a variety of customer sites. We thoroughly inspect all equipment, including hoods, filters, and ducts and all equipment will be tested in accordance with HSE guidelines for LEV testing. This ensures that all equipment is correctly assessed, and you can aim for maximum effectiveness for your LEV system. A detailed report is created that specifics all system equipment, sketches, test readings, and any necessary corrective work. Our engineers all have years of experience and are highly qualified to conduct the LEV test and review your system.

We provide COSHH compliant LEV testing on all extraction systems at a variety of customer sites. We thoroughly inspect all equipment, including hoods, filters, and ducts and all equipment will be tested in accordance with HSE guidance for ventilation systems and LEV testing. This ensures that all equipment is correctly assessed, and you can aim for maximum effectiveness for your fume extraction system. A detailed report is created that specifics all system equipment, sketches, test readings, and any necessary corrective work. Our engineers all have years of experience and are highly qualified to conduct the LEV test and review your system in accordance with HSE guidance for ventilation systems and LEV testing in a clean condition, ensuring the technical performance of your fume extraction system is up to standard.

LEV or Local Exhaust Ventilation is an engineering system frequently used in the workplace to protect employees from hazardous substances. This applies to any oil mist, welding fume, smoke and dust extraction units.

A Local Exhaust Ventilation (LEV) test is defined as a

“Detailed and systematic examination sufficient to make sure that the LEV system can continue to perform as intended by design and will contribute to the adequate control of exposure. The thorough examination would normally include such functional testing to provide sufficient evidence to indicate adequate control is being achieved.”

The regulations for LEV testing companies are set out by the Health and Safety Executive (HSE) in the Control of Substances Hazardous to Health (COSHH) guidelines. It’s mandatory that every employer should maintain working conditions for the employees, and any employer who uses LEV techniques in the workplace must have the equipment examined and tested. COSHH (Control of Substances Hazardous to Health) regulations require a competent person to undertake the LEV System and provide a report based on the outcome of the LEV Test. A competent and P601 qualified engineer will provide each lev system with a compliance status and report outlining all the findings in accordance to HSE regulation and guidelines (www.hse.gov.uk). This includes ensuring that the LEV equipment is maintained in an efficient state, in efficient working order, and in good repair. For more information on hazardous substances visit www.hse.gov.uk/cleaning/topics/coshh.htm

It is a legal requirement of COSHH (Control of Substances Hazardous to Health) regulations for each LEV system to be tested every 14 months to ensure it’s working effectively and safely. Some LEV systems will require more frequent testing depending on their application.

This applies to all oil mist, welding fume, smoke and dust extraction units and any systems that produces airborne contaminants within your working environment. This examination must be undertaken by a competent person and the tests and reports must conform to HSE standards. HSG258 provides the recommended procedures to achieve these work act statutory requirements.

Our lev engineers hold the BOHS P601 certification, which is one measure of competency in this area. We pay close attention to the HSE guidelines while undertaking any examination, maintenance, or repair work.

Although, regular lev testing is a legal requirement, lev servicing should also take place for a peace of mind and provide a safe working environment that ensures good control measures are always in place. We can provide lev servicing of each and every local exhaust ventilation system which can be included in an overall maintenance package.

Simply fill in your name and email address. And we will be in touch shortly.

We will schedule you a date with one of our competent engineers that is suitable for you.

Ensuring all appropriate documentation is sent out.

The engineer will arrive, following all agreed site conditions and perform LEV Testing on the agreed LEV Systems set out in the RAMS in accordance to HSE guidelines.

LEV system feedback and a comprehensive report will follow.

If the system PASSES the lev testing requirements, all the documentation will be sent out digitally as proof of certification.

If a system does not meet regulatory requirements, it will have FAILED its lev testing . However, we will give our recommendations for your lev system and provide you with a quote and implement any remedial works to get you fully operational, compliant and in good working order; so to remove any harmful substances.

The reports and certifications that we provide are legal documents that include the following:

Note: The documentation can be used for insurance requirements and must be held on file for 10 years.

LEV testing should be conducted at least every 14 months, as recommended by the Health and Safety Executive (HSE). However, the frequency of testing may vary depending on factors such as the type of contaminants, the nature of the work processes, and any specific recommendations from manufacturers or industry guidelines. It is important to consult the HSE guidelines and assess the specific requirements of your workplace to determine the appropriate frequency for LEV testing.

LEV testing can be performed in-house if you have a competent person with the necessary knowledge, skills, and experience in LEV testing. This person should have completed relevant training courses and be familiar with industry standards and regulations. It is important to ensure that the in-house testing meets the requirements set by the Health and Safety Executive (HSE) and any other applicable regulatory authorities.

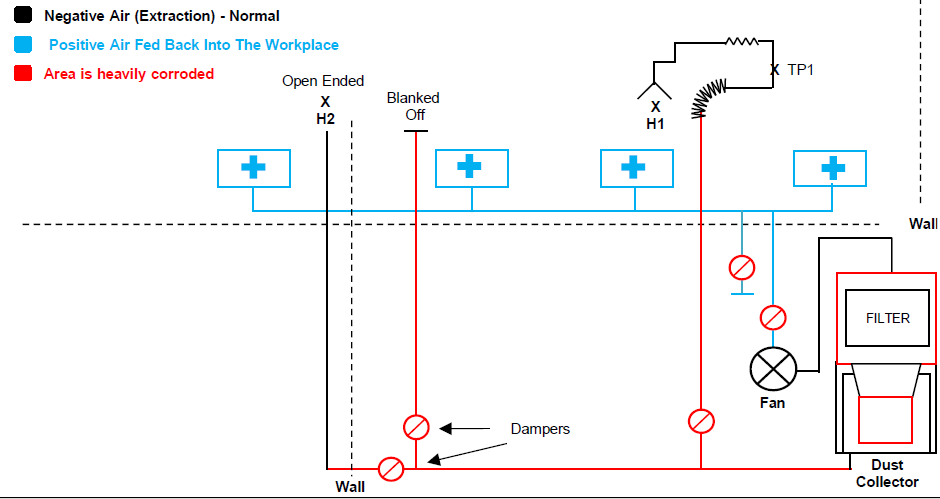

During LEV testing, common issues that may be found include inadequate airflow, leaks in the ducting or extraction hood, filter blockages, and improper positioning of hoods or extraction points. These issues can impact the effectiveness of the LEV system in controlling fumes, dust, and other airborne contaminants.

To prepare your workplace for LEV testing, ensure that all extraction points, hoods, and ductwork are accessible and free from any obstructions. Clear the work area of any potential hazards and ensure that employees are aware of the testing process. It is also important to review any previous test reports or maintenance records to identify any recurring issues that may require special attention during the test.

T/A LEV Extraction Services

Reg Company: Panaceair Ltd

Registered Address: 16 The Croft, Euxton, Chorley, PR7 6LH

Company Number: 11174051

VAT Reg No: 442 171 031

© 2023 By LEV Extraction Services. All Rights Reserved.